- SAIC

IMMERSION WELL REACTORS

A variety of Immersion Well Photochemical

Reactors are available for the synthetic photochemist engaged in synthesis

employing halogenation, exidation, or degradation methods. The reactors

are designed to be efficient and include provision for irradiation

by low or medium pressure mercury lamps. Double-walled immersion wells

(in quartz or borosilicate glass) permit water cooling of lamps or

filtering of excitation radiation. Various reaction flasks enable

irradiations to be conducted under anaerobic conditions at low or

constant temperature.

LAMPS & POWER SUPPLIES:

Low pressure mercury lamps emit over

90% of their energy at 254nm providing a useful source of ultra-violet

radiation for photo reactions. Medium pressure mercury lamps have

much more intense arcs and radiate predominantly 365-366nm light with

smaller amounts in the ultra-violet region at 265, 297, 303 and 313

nm as well as significant amounts in the visible region at 404-408,

546 and 577-579nm. The choice of lamp power and lamp is determined

to some extent by the nature of the photoreaction and volume of reactant

solution.

Low pressure Mercury Vapour Lamp:

| Nominal Wattage | Diameter in mm | Lamp Model | Power Supply Model |

|---|---|---|---|

| 6 | 14 | MVL 1 | MVL 11 |

| 12 | 26 | MVL 2 | MVL 21 |

Medium Pressure Mercury Vapour Lamp:

| Nominal Wattage | Diameter in mm | Lamp Model | Power Supply Model |

|---|---|---|---|

| 125 | 20 | MVL 3 | MVL 31 |

| 400 | 22 | MVL 4 | MVL 41 |

Arc sources possess negative voltage-current

characteristics, i.e. the voltage drop across the lamp decreases as

the current through the lamp increases and conventional low-impedance

power supplies cannot be used. Lamps must be operated from reactive

type supplies having a large resistance or inductance in series to

provide extra power to initiate the arc and reduced power for continuous

operation.

IMMERSION WELLS:

These are double-walled wells, made

in Quartz or Borosilicate Glass, which house the lamp. Inlet and outlet

tubes provide for air or water cooling. A small diameter inlet tube

extends to the bottom of the annular space to allow coolant flow from

the bottom of the well upwards. A 2-3mm spacing between the walls

allows filtering of certain wavelengths (with liquids, e.g.cobalt,

nickel or copper sulphate solutions or with gases, e.g.chlorine) to

reduce secondary photochemical reactions of products. Note that borosilicate

glass does not transmit 254nm radiation.

Immersion Well Dimensions:

| Overall Length (mm) | Outside Diameter (mm) | Joint | Quartz Well | Borosilicate Well |

|---|---|---|---|---|

| 265 | 38 | 45/50 | QW1 | BW1 |

| 390 | 64 | 70/60 | QW2 | BW2 |

Reaction Flasks:

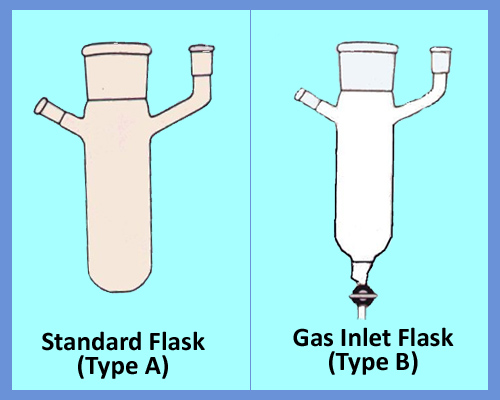

Two types of outer reaction flasks

are available. All are made of borosilicate glass and are fitted with

one central ground socket (to take an immersion-well) and other smaller

sockets for a reflux condenser or dropping funnel, sampling port etc.

Flasks may be supported by conventional laboratory stands and clamps.

Standard Flask (Type A):

Cylindrical flask with flattened

bottom for magnetic stirrer bar. Provided with one angle socket and

one vertical socket. (PTFE tubing for gaseous agitation may be fed

through the socket). Suitable for low/constant temperature irradiation.

Gas Inlet Flask (Type B):

As standard flask with additional

sintered glass disc (dedium porosity) fitted to bottom of flask to

permit gas agitation and allow the reaction mixture to be kept under

an inert or reactive atmosphere. A glass PTFE stopcock is attached.

Reaction Flask Dimensions:

| Reactant Capacity Nominal (mm) | Length (mm) | Joint | Flask Type | Model | |

|---|---|---|---|---|---|

| A Std | B Gas Inlet | ||||

| 150 | 215 | 45/40 | * | A/150 | |

| 200 | 310 | 70/60 | * | A/250 | |

| 150 | 315 | 45/40 | * | B/150 | |

| 200 | 400 | 70/60 | * | B/200 | |

| 400 | 400 | 70/60 | * | B/400 | |

Reflux Condenser:

A double surface reflux condenser,

prevents `creep' and loss of vapour when low boiling point liquids

are used. Will fit all types of reaction flasks. Model RC1.

Complete Immersion Well Reactors:

The following table describes the

various Immersion Well Reactors and which are supplied complete with

Reflux Condenser.

| Model | IWQ1 | IWB1 | IWQ2 | IWB2 |

|---|---|---|---|---|

| Lamp/Power Supply | 6 W | 125 W | 12 W | 400 W |

| Immersion Well | QW1 | BW1 | QW2 | BW2 |

| Reaction Flask | B/150 | B/150 | B/200 | B/200 |

Note: Full details of liquid cut-off

solutions are supplied with the instruction manual.