- SAIC

UV TECHNOLOGY

Ultraviolet reactive substance eg.

inks and coatings require a high intensity source of ultraviolet light

to initiate a chemical reaction and the curing of the ink or the coatings

take place almost instantaneously.

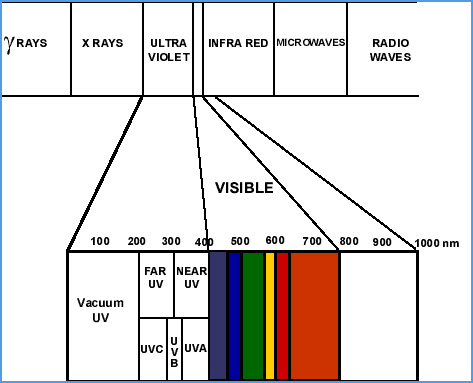

The electromagnetic spectrum ranges from radio waves at the long-wave end to x-rays and gamma rays at the short-wave end and ultraviolet light is a small part this spectrum.

The drawing given below shows where the ultraviolet wavelengths fit in the electromagnetic spectrum.

The electromagnetic spectrum ranges from radio waves at the long-wave end to x-rays and gamma rays at the short-wave end and ultraviolet light is a small part this spectrum.

The drawing given below shows where the ultraviolet wavelengths fit in the electromagnetic spectrum.

Electromagnetic Spectrum:

The ultraviolet wavelengths lie

between 200 and 400 nm are most suitable for the curing of inks.

Various types of lamps suitable for generating these wavelengths are available and the main ones being high pressure mercury arc lamps, lamps without electrodes and medium pressure mercury arc lamps.

The high pressure mercury arc lamp is generally constructed as a capillary type tube generate heat and requires a water circulation to maintain correct running temperatures. These lamps have short lengths and lamp life is usually less than 2000 hours.

The electrode-less mercury arc lamp does not have electrodes. An arc is established by the generation of micro-waves. These types of lamps are generally produced in two standards lengths, 6 inch and 10 inch.

By far, the most widely used is the medium pressure mercury arc lamp (an MPMA Lamp). This can be air or water-cooled and can be manufactured in a wide range of lengths. Single lamps of two metres long are not uncommon, and the working life of MPMA lamps can be expected to be around 2000-2500 hours.

The body of the lamp is made from transparent vitreous-silica tube of various diameters and wall thicknesses. This material, referred to as quartz, has important properties vital to the efficient operation of an ultraviolet system. It has 90% transparency to ultraviolet light, whereas normal glass filters out all except the longer, weaker wavelengths. The surface temperature of an ultraviolet lamp under normal operating conditions is between 600'C and 800'C. Quartz is able to withstand these temperatures as it has a very low thermal expansion characteristic and high melting temperature.

The electrodes, from which the high voltage arc is sustained, are made from a tungsten rod and with tungsten wire. Tungsten is necessary to withstand internal arc temperatures over 3000'C. Electrodes must be designed carefully to ensure efficient, reliable operation and long lamp life. The parameters affecting this design are extremely complex.

Because of the extremely high running temperatures, and the low expansion characteristic of the quartz, the correct selection of a suitable material to connect the electrode inside the envelope, to the power supply on the outside of the envelope, is extremely important.

Molybdenum foil which has a low coefficient of expansion and is capable of carrying the high voltage required to sustain a stable arc.

Additional electrical connections are made using high temperature wire. Electrical insulation at the end of the lamp can be achieved by the use of a ceramic end cap.

Various types of lamps suitable for generating these wavelengths are available and the main ones being high pressure mercury arc lamps, lamps without electrodes and medium pressure mercury arc lamps.

The high pressure mercury arc lamp is generally constructed as a capillary type tube generate heat and requires a water circulation to maintain correct running temperatures. These lamps have short lengths and lamp life is usually less than 2000 hours.

The electrode-less mercury arc lamp does not have electrodes. An arc is established by the generation of micro-waves. These types of lamps are generally produced in two standards lengths, 6 inch and 10 inch.

By far, the most widely used is the medium pressure mercury arc lamp (an MPMA Lamp). This can be air or water-cooled and can be manufactured in a wide range of lengths. Single lamps of two metres long are not uncommon, and the working life of MPMA lamps can be expected to be around 2000-2500 hours.

The body of the lamp is made from transparent vitreous-silica tube of various diameters and wall thicknesses. This material, referred to as quartz, has important properties vital to the efficient operation of an ultraviolet system. It has 90% transparency to ultraviolet light, whereas normal glass filters out all except the longer, weaker wavelengths. The surface temperature of an ultraviolet lamp under normal operating conditions is between 600'C and 800'C. Quartz is able to withstand these temperatures as it has a very low thermal expansion characteristic and high melting temperature.

The electrodes, from which the high voltage arc is sustained, are made from a tungsten rod and with tungsten wire. Tungsten is necessary to withstand internal arc temperatures over 3000'C. Electrodes must be designed carefully to ensure efficient, reliable operation and long lamp life. The parameters affecting this design are extremely complex.

Because of the extremely high running temperatures, and the low expansion characteristic of the quartz, the correct selection of a suitable material to connect the electrode inside the envelope, to the power supply on the outside of the envelope, is extremely important.

Molybdenum foil which has a low coefficient of expansion and is capable of carrying the high voltage required to sustain a stable arc.

Additional electrical connections are made using high temperature wire. Electrical insulation at the end of the lamp can be achieved by the use of a ceramic end cap.

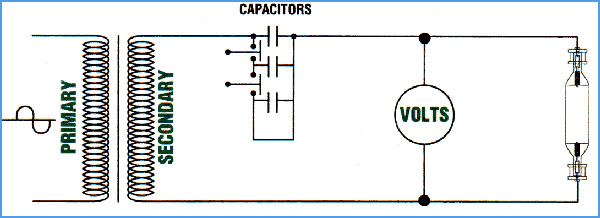

Electrical Requirements For Medium Pressure Mercury Arc Lamps:

Due to the electrical nature of

a medium pressure mercury arc lamp, mains voltage alone is usually

insufficient to operate the lamp. Therefore a step-up transformer

is used. These transformers have to be correctly matched to the electrical

demands of each lamp size and type.

Lamp control can be performed by the use of either an inductive, or a capacitive system. With an inductive system, the lamp is connected directly to the output of the transformer. When any fluctuation of the input voltage occurs, the output of the transformer also varies proportionately. This then alters the output of the lamp. With a drop in input voltage the lamp output will drop proportionately.

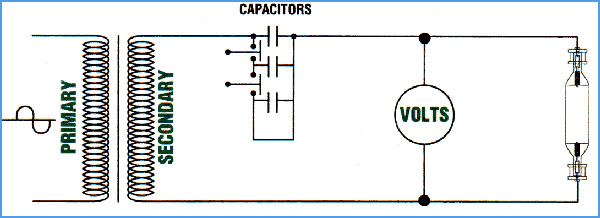

The capacitive system overcomes this problem by the use of capacitors connected in series with the lamp. This has the effect of maintaining a constant output to the lamp whilst inputs may vary. This is known as a constant-wattage system and is, by nature of its design, the most efficient.

SAIC Lamp Control Box are designed to run as constant wattage capacitive systems. The diagram shows the electrical circuit required to control the running of such a lamp.

To ensure that the highest efficiency is obtained from SAIC lamps, the transformers and the control circuitry are designed and manufactured in-house to very specific standards.

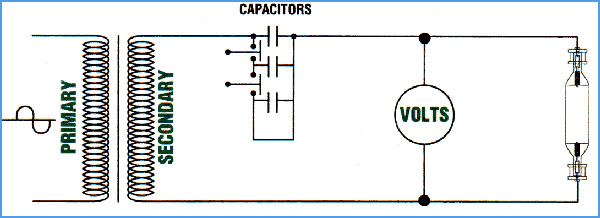

Lamp control can be performed by the use of either an inductive, or a capacitive system. With an inductive system, the lamp is connected directly to the output of the transformer. When any fluctuation of the input voltage occurs, the output of the transformer also varies proportionately. This then alters the output of the lamp. With a drop in input voltage the lamp output will drop proportionately.

The capacitive system overcomes this problem by the use of capacitors connected in series with the lamp. This has the effect of maintaining a constant output to the lamp whilst inputs may vary. This is known as a constant-wattage system and is, by nature of its design, the most efficient.

SAIC Lamp Control Box are designed to run as constant wattage capacitive systems. The diagram shows the electrical circuit required to control the running of such a lamp.

To ensure that the highest efficiency is obtained from SAIC lamps, the transformers and the control circuitry are designed and manufactured in-house to very specific standards.

Spectral Output Of An MPMA Lamp

As has been stated earlier, the

achievement of the precise wavelengths of ultraviolet light suitable

for curing ultraviolet inks and coatings is very important if a system

is to be highly efficient.

MPMA lamps emit not only ultraviolet light, but also visible light, and wavelengths in the infrared spectrum. In fact, all lamps emit approximately 20% ultraviolet light, 60% infrared light and 20% visible light. It is therefore important that when selecting a lamp, output in the ultraviolet spectrum should be closely examined.The ultraviolet spectral output is sometimes expressed graphically, showing the proportional output at the important ultraviolet wavelengths. A graph of a typical SAIC MPMA lamp is shown below.

MPMA lamps emit not only ultraviolet light, but also visible light, and wavelengths in the infrared spectrum. In fact, all lamps emit approximately 20% ultraviolet light, 60% infrared light and 20% visible light. It is therefore important that when selecting a lamp, output in the ultraviolet spectrum should be closely examined.The ultraviolet spectral output is sometimes expressed graphically, showing the proportional output at the important ultraviolet wavelengths. A graph of a typical SAIC MPMA lamp is shown below.

Lamp Life

Medium-pressure mercury arc lamps

do not normally fail suddenly, as do ordinary household light bulbs.

Efficiency declines relatively slowly, until insufficient UV light

is being emitted for the lamp to cure effectively. This decline is

caused primarily by the deterioration in UV transparency of the quartz

jacket, and depends on a number of factors:- lamp cooling efficiency,

power rating, current rating of the electrodes, electrode cooling

efficiency, contamination of the lamp's external surface (dust etc.)

and switching frequency.

When correctly used, SAIC UV Curing Lamps are guaranteed to produce a high level of curing efficiency for at least 2000 hours and, with proper handling, they will still be capable of delivering at least 80% of original output.

When correctly used, SAIC UV Curing Lamps are guaranteed to produce a high level of curing efficiency for at least 2000 hours and, with proper handling, they will still be capable of delivering at least 80% of original output.

Precautions to be taken while using UV

UV can cause allergic reactions

in users who are sensitive and can have skin irritation. It is always

a good idea to wear protective clothing, including eye and hand protection,

when handling UV .

Besides UV energy, UV lamps also emit very bright visible light that could be harmful to the eyes if workers are exposed to it frequently or for long periods. This is why it is important to block light from escaping through the curing-chamber conveyor openings by installing shields.

One other safety issue to keep in mind concerns ozone, which is a very unstable molecule of oxygen. Ozone is generated when an electric discharge passes through air (e.g., lightening) or when oxygen is exposed to high-intensity UV energy. Ozone generated can lead to respiratory problems for those who work near the uv units, so it's important to make sure that such places are well vented to evacuate ozone from the work area.

Besides UV energy, UV lamps also emit very bright visible light that could be harmful to the eyes if workers are exposed to it frequently or for long periods. This is why it is important to block light from escaping through the curing-chamber conveyor openings by installing shields.

One other safety issue to keep in mind concerns ozone, which is a very unstable molecule of oxygen. Ozone is generated when an electric discharge passes through air (e.g., lightening) or when oxygen is exposed to high-intensity UV energy. Ozone generated can lead to respiratory problems for those who work near the uv units, so it's important to make sure that such places are well vented to evacuate ozone from the work area.

Applications:

| Low-pressure Mercury Lamp | High-pressure Mercury Lamp |

|---|---|

| 1. Photo cleaning Photo surface processing 2. Photo oxidation water treatment Accelerated oxidation water treatment 3. Cracking of sparingly decomposable organic gases 4. Ozonizing and ozonolysis 5. Ionization and deionization 6. Sterilization Evoked spawning of shellfish 7. Deletion of IC memory 8. Photo ashing and photo CVD |

1. UV curing 2. Photo polymerizing reaction 3. Photo oxidation water treatment Accelerated oxidation water treatment 4. Sterilization |